A Five-Acre Regenerative Urban Farm for Maximum Food Production

This system is built on the core insight demonstrated by Will Allen:

Living soil and living water must remain connected, even when that increases maintenance.

Most modern aquaponic systems attempt to sterilize and simplify. Allen accepted biological complexity in exchange for productivity and resilience. This design extends that principle to perennial crops, protein production, and full urban food security.

It is not hobby farming.

It is infrastructure.

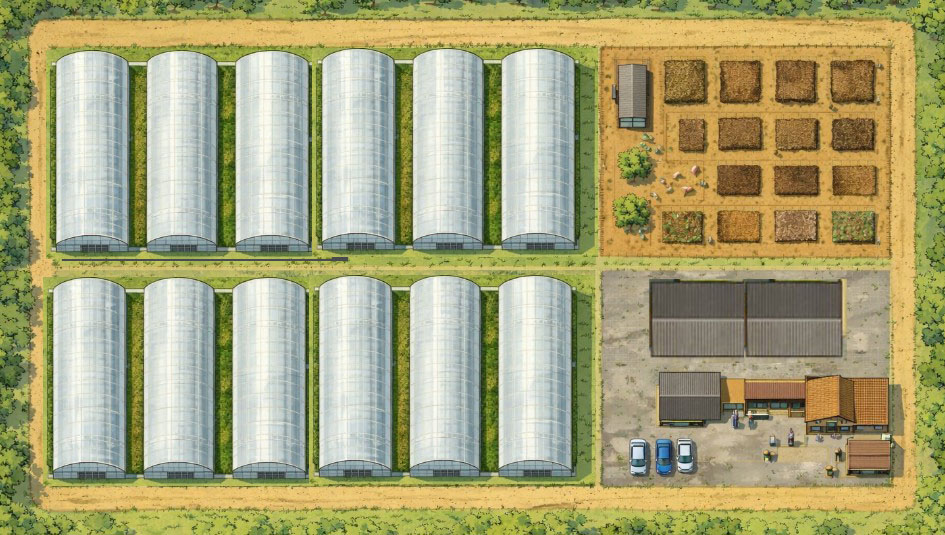

Site Overview (5 Acres Total)

1) Greenhouse Production Zone — 3 Acres

Three acres of passive-solar greenhouses optimized for season extension without mandatory supplemental heat.

Design features:

- South-facing orientation

- Double-wall poly

- Thermal mass (water tanks, masonry, soil beds)

- Earth berming where possible

- High rooflines

- Automated ventilation

- Shade management

Goal:

Four-season production without structural dependence on fossil fuel heat.

Heating remains optional.

The system must function without it.

2) Poultry & Biomass Cycling Zone — 1 Acre

(Mobile Tractor + Distributed Compost System)

This acre functions as the biological digestion system of the farm.

It uses:

- Mobile chicken tractors

- Rotational paddocks

- Distributed mulch windrows

- Targeted decomposition

There is no permanent coop footprint.

Birds are housed at night in mobile tractors and released daily into active paddocks.

This prevents manure accumulation and disease vectors while maximizing compost processing.

Paddock Layout

- 10–14 rotating paddocks

- Central is

- Tractor access lanes

- Windrows inside each paddock

Rotation cycle: 30–45 days minimum.

This fully disrupts parasite and pathogen buildup.

Compost & Mulch Management

Each paddock contains staged windrows:

- Fresh biomass

- Mid-stage compost

- Fungal-dominant breakdown

- Finished mulch

Chickens are rotated to the paddock with the highest insect activity.

They instinctively target the most biologically productive material.

No mechanical turning required.

Daily Operation

Morning:

- Move tractor

- Release birds

Day:

- Birds work windrows

- Consume pests

- Fertilize soil

Evening:

- Recall to tractor

- Secure housing

Next day:

- Move again

No buildup.

No stagnation.

No permanent contamination.

Outputs

- Eggs

- High-quality compost

- Finished mulch

- Nitrogen-rich litter

- Pest suppression

This acre replaces:

- Fertilizer inputs

- Waste hauling

- Mechanical composting

- Chemical pest control

3) Operations & Market Zone — 1 Acre

Includes:

- Wash/pack facility

- Cold storage

- Dry storage

- Tool shop

- Fish processing area

- Office / classroom

- Farm store

- Parking

- Loading dock

This isolates logistics from production.

No cross-contamination.

Aquaculture Core

Two primary fish systems.

Tank Group A: Channel Catfish

- High biomass

- High fat

- High nutrient output

- Primary fertilizer engine

Tank Group B: Yellow Perch

- Cleaner feeding profile

- High market value

- Balanced production

Management Model

- Continuous fry stocking

- Rolling harvest

- Size-based removal

- No batch cycles

Feeding is intentionally generous (within oxygen limits).

Goal:

Maximize protein growth and nutrient production.

This creates “fertile water.”

Not sterile water.

Living Water Distribution

Instead of full sterilization:

- Settling basins

- Bioactive sumps

- Worm filters

- Mineral beds

- Living media beds

Solids are managed biologically.

Water remains alive.

This follows Allen’s soil-in-the-loop principle.

Integrated Food Forest (4 Layers Powered by Fish Water)

Fish effluent drives four perennial layers within and adjacent to greenhouses.

1) Dwarf & Semi-Dwarf Fruit Trees

Grown in large containers/barrels:

- Apple

- Pear

- Plum

- Cherry

- Fig

Root zone: living soil

Interface: flowing nutrient water

Riparian orchard model.

Trees function as permanent nutrient sinks.

2) Fruiting Shrubs

Primary species:

- Mulberry (dual-use: human + poultry)

- Blueberry

- Raspberry

- Blackberry

- Currant

- Gooseberry

Mulberry is strategic:

High yield

High sugar

Livestock feed

Zero processing

3) Vines & Climbers

Trellised on greenhouse structure:

- Grapes

- Hardy kiwi

- Passionfruit (warm zones)

- Cucumbers

- Squash

Vertical calorie production.

No wasted airspace.

4) Annual Greens & Herbs

Fast-turnover production:

- Lettuce

- Spinach

- Kale

- Chard

- Basil

- Cilantro

- Parsley

- Like

- Dill

- Scallions

Primary cash-flow crops.

High frequency income.

Nutrient Loop

Complete biological cycle:

Fish → Water → Plants → Waste → Chickens → Compost → Soil → Plants

No waste streams.

No external disposal.

Calorie Strategy

This is not “salad farming.”

It prioritizes:

Protein

Fat

Sugar

Starch

Micronutrients

Sources:

Fish → protein/fat

Eggs → protein/fat

Fruit → sugars

Greens → vitamins

Grapes → preserves

Mulberry → animal feed

This supports subsistence and market production.

Labor Structure

Designed for:

- 8–12 full-time staff

- 10–20 seasonal

- Apprentices

All cross-trained.

No siloed expertise.

Expected Annual Output (Conservative)

Fish: 60–90 tons

Produce: 500k–800k lbs

Eggs: 250k–350k

Fruit: 80k–120k lbs

Revenue:

$2.5M–$5M+ annually

Without subsidies

Why This Works

- Biology replaces machinery

- Perennials stabilize income

- Waste is eliminated

- Energy demand is minimized

- Maintenance is accepted, not avoided

This is Allen’s philosophy scaled.

Giving Will Allen Proper Credit

Allen proved:

- Soil belongs in aquaponics

- Waste is value

- Community matters

- Complexity builds resilience

This model extends:

- Perennials

- Protein scaling

- Market integration

- Infrastructure permanence

It is not a new philosophy.

It is the full build-out.

Final Assessment

This system is:

Technically feasible

Biologically stable

Financially viable

Regionally scalable

It represents what urban food infrastructure should be.

Not boutique.

Not fragile.

N

Permanent.