Trash Is a Battery Resource We’re Throwing Away

Every time we talk about batteries, the conversation goes the same way.

Lithium.

Cobalt.

Nickel.

Rare earths.

Supply chains.

China.

Mines.

We argue about where to dig next.

We almost never ask a better question.

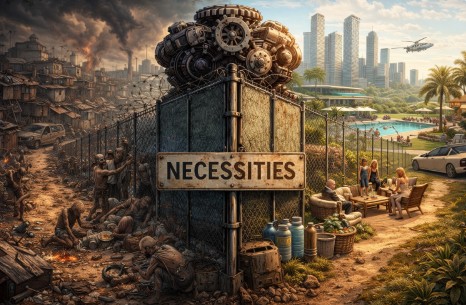

Why are we burying and burning the materials we could be using?

Modern Batteries Are Carbon-Intensive Products

Most people think batteries are “metal technology.”

They are not.

They are carbon systems with metal components.

Every lithium-ion battery depends on carbon:

Graphite anodes.

Carbon binders.

Carbon additives.

Carbon coatings.

Carbon structures.

Without high-quality carbon, batteries do not work.

And right now, most of that carbon is imported, mined, or chemically synthesized at high cost.

Meanwhile, we throw away millions of tons of carbon-rich material every year.

Our Waste Stream Is a Feedstock Stream

Look at what goes into a landfill:

Paper.

Cardboard.

Food waste.

Wood.

Textiles.

Plastics.

Packaging.

Agricultural residue.

This is not “garbage.”

It is unrefined biomass and polymer feedstock.

It is carbon, hydrogen, oxygen, and trace minerals in convenient piles.

Right now, municipalities pay to bury this material, then pay again to import the products it could have become.

We just do not treat it that way.

Pyrolysis: Turning Waste Into Industrial Inputs

Pyrolysis is simple in concept.

Heat material in the absence of oxygen.

It does not burn.

It breaks down.

You get three products:

Solid carbon (char / hard carbon)

Condensable oils

Combustible gases

No incineration.

No massive smokestacks.

No ash mountains.

Just controlled thermal decomposition.

This is not experimental.

It is industrial chemistry that has existed for generations.

We just never integrated it into municipal systems.

Hard Carbon Is the Missing Link

Here is where this gets important.

Pyrolysis produces hard carbon.

Not soft graphite.

Hard, disordered, porous carbon.

This is exactly what next-generation batteries want.

Sodium-ion batteries.

Potassium-ion batteries.

Hybrid lithium systems.

Grid-scale storage.

All of them are moving toward hard carbon anodes.

Because:

It is cheaper.

It tolerates impurities.

It handles temperature better.

It uses abundant materials.

We are standing on mountains of it.

The Price of Batteries Is a Waste Problem

Battery costs are not driven only by metals.

They are driven by:

Refining.

Transport.

Purification.

Energy input.

Supply volatility.

When you source carbon locally from waste:

You cut shipping.

You cut mining.

You cut processing.

You cut geopolitical risk.

Every town with a waste stream becomes a potential materials supplier.

That is decentralization.

That is resilience.

Realcycling: Closing the Materials Loop

“Recycling” usually means:

Collect → ship → sort → downcycle → discard.

Realcycling means:

Recover → refine → reuse → re-enter production.

With pyrolysis, you can:

Process mixed waste.

Stabilize plastics.

Extract usable carbon.

Recover oils for fuels or chemicals.

Generate process heat.

Nothing leaves as “trash.”

It leaves as inventory.

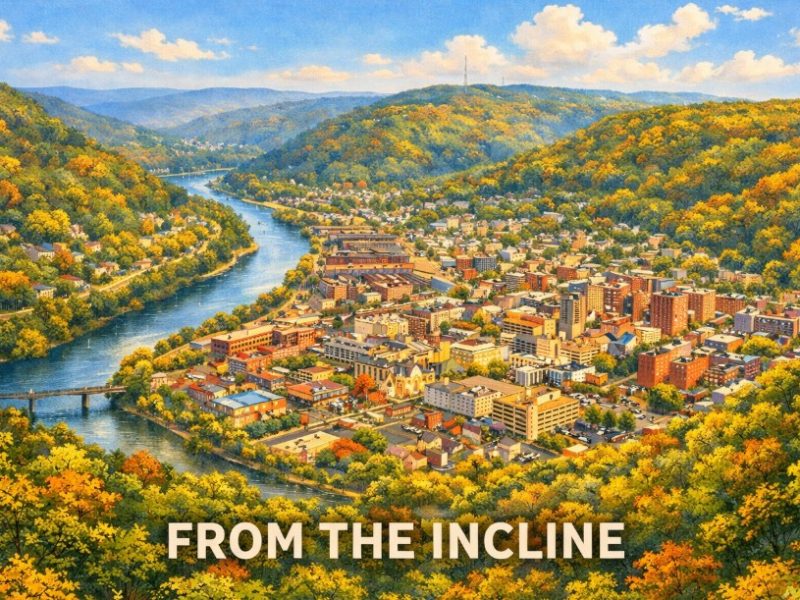

Municipal Systems Could Be Material Plants

Imagine if every regional waste facility included:

A pyrolysis line.

Carbon upgrading equipment.

Quality control lab.

Battery-material prep unit.

Instead of paying to bury waste, cities would sell:

Hard carbon.

Carbon black.

Industrial char.

Chemical feedstocks.

Synthetic fuels.

Waste departments become manufacturing departments.

That is a mindset shift.

This Unlocks Local Battery Manufacturing

Cheap carbon unlocks everything else.

When anodes are affordable and local:

Cell assembly follows.

Module plants follow.

Storage integrators follow.

Grid projects follow.

You stop importing finished batteries.

You start exporting components.

That is how industrial ecosystems form.

Environmental Gains Without Fantasy

This is not greenwashing.

It reduces:

Landfill methane.

Plastic leakage.

Open dumping.

Long-haul waste transport.

Mining pressure.

And it does it with existing physics.

No miracles required.

This is not a technology problem.

It is a systems problem we keep choosing not to solve.